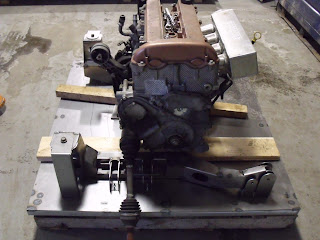

Well I am re-mounting the engine into the custom frame, today I dropped the engine on the subframe jig, I changed the front transmission mount to a LSJ mount from a Cobalt SS. Also I will be changing the top transmission mount and top engine mount to LSJ units from my ION. Tomorrow will bring about some more measuring and designing.

88 custom engine cradle fabrication part 2

Did a little more welding today, unfortunately I was running late this morning due to a late night watching Vitor getting kicked in the face by Silva, but I did manage to get the second half of the side rails tack welded together today. I ran into a small problem with the first piece, there was a angle problem and the two pieces weren't parallel, I had to cut and change the angle which caused the front piece to be 3/8" shorter, and the front mounting hole and trailing arm holes aren't in the right location. I am going to have to work on this next week, I have two ways to fix it, both will involve more welding........

Weekend of welding

Today was a busy one, before welding the custom 88 style subframe I wanted to finish a couple other little projects that were just waiting to be done. First one was hard mounting the intercooler, very simple setup thats going to take air from over the roof via a large bird catcher and ram it into the intercooler, to keep engine bay temps down I am going to be venting the deck lid and possibly something with the rear bumper or the rear tail lights. Second thing was to cut out the stock 85 strut location and weld in my 88 location plates with top camber adjustment plates. Last thing I got down was the tack welding of the first piece of the subframe and did a test fit into the engine cradle jig.......one thing you will notice is that I don't have proper bolts, rather sharpies and drill bits holding the points, I forgot to bring in some M12 bolts, I will bring them in shortly. Not sure what tomorrow will bring, still working on a small problem with the cooling system on the 3800SC swapped daily driver Fiero which I will be modifying a stock 2.8L engine fill cap w/thermostat to work on the 3800, so this will take a hour or two out of tomorrows project time.

88 custom engine cradle fabrication

Well I have started it, the first pieces are off the laser and brake, there are a couple issues that might require some "creative hammering", that is if the pieces are close to the proper design/dimensions in the critical areas. If they are not I will be going back to the drawings, making the adjustments and rebuilding the parts. I hope this isn't the case because I am hoping to have a great weekend of progress, here are the pics of the current state.

88 custom engine cradle mock up

So the last couple days I've been busy working on the design for the custom engine cradle to support the 2.0L Ecotec motor and transmission, I'm also updating the suspension to a 88 Fiero setup with proper multilink and trailing arm.

Right now the design is mostly made on autocad, but I have started mocking up pieces in bristol board (old school yes I know) but thanks to CCFiero, he's great with Solid edge and is also helping me out with some 3D renderings as well. Still gotta work out a couple issues with my flat design so that I can close up some gaps, I think the design is coming up nicely, the main side rails are mainly made out of 2 pieces of 0.120 thick mild steel, when all bent up the two pieces will come together and create a single rail piece.

Anyways onto a few pics, also shown is the autocad flat design to show how interesting the pieces are before bending.

Right now the design is mostly made on autocad, but I have started mocking up pieces in bristol board (old school yes I know) but thanks to CCFiero, he's great with Solid edge and is also helping me out with some 3D renderings as well. Still gotta work out a couple issues with my flat design so that I can close up some gaps, I think the design is coming up nicely, the main side rails are mainly made out of 2 pieces of 0.120 thick mild steel, when all bent up the two pieces will come together and create a single rail piece.

Anyways onto a few pics, also shown is the autocad flat design to show how interesting the pieces are before bending.

Rear engine cradle jig

This past weekend I built a jig so I could junk the current engine cradle and the 84-87 rear suspension setup for a 88 style setup, now I have to design the pieces that will make up the rear cradle and new engine mounts, there is still some welding that I haven't completed (busted the ceramic shield on the TIG welder and couldn't continue), I will also be changing some of the current mounts to proper LSJ mounts from the ION donor car. I've also completed the designs of the control arms for the rear suspension setup, now I just have to get some bushings and some tubing and those will be done.

Special thanks to R_Rourke who let me borrow his 88 cradle and suspension for mock up and measurements, also to CCFiero who's been helping out with the design of this project.

Welding on the intake manifold is complete

Got the intake manifold welded and back today, they did an amazing job on it, there is a big problem that I am going to have to work on, unfortunately I didn't do enough test fitting and the intake plenum is in the way of the engines coolant line, I already have a couple idea's to get around this issue, so it shouldn't be that bad.

Subscribe to:

Posts (Atom)