Got the intake manifold welded and back today, they did an amazing job on it, there is a big problem that I am going to have to work on, unfortunately I didn't do enough test fitting and the intake plenum is in the way of the engines coolant line, I already have a couple idea's to get around this issue, so it shouldn't be that bad.

Intake polished and ready for final welding

Why is it all the pretty parts have to be hidden? First the fire cone in the exhaust header, now the polished intake runners.

Going for final welding in a couple hours.

Intake manifold is coming along

Well its finally coming along, I cleaned up the welds over the last couple days and tonight I wet sanded and started preparing it for polishing tomorrow. I am hoping to drop off the runners, plenum and throttle body plate off for final welding tomorrow, maybe it will be done after the weekend.

Intake manifold welding

Got the intake manifold piece back from welding this morning, the welder did an amazing job, and when I am done cleaning up the runners the piece will be going back to have the plenum all welded up.

Quick update

I had to send out the aluminum intake for welding, my poor welder and my skills just couldn't handle welding 3/8 and 1/2" material to much thinner aluminum material, I hope to have something more to post with it this week with some progress pictures.

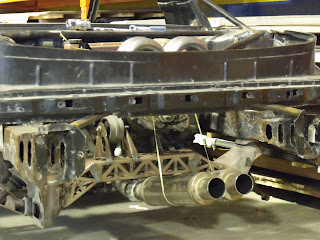

Going onto other things, I have gotten many of my suspension parts in, at least enough to start on it, although I do need to stop at the metal shop and get some tubular piping for the polyurethane bushings and arms.

Unfortunately I'm still doing a ton of work to my daily driver so I am hoping to have a few things updated shortly.

Going onto other things, I have gotten many of my suspension parts in, at least enough to start on it, although I do need to stop at the metal shop and get some tubular piping for the polyurethane bushings and arms.

Unfortunately I'm still doing a ton of work to my daily driver so I am hoping to have a few things updated shortly.

Exhaust welding complete and mounting.

Finished the last of the welding to the exhaust and downpipe, welded the hanger to the frame and installed everything. I think it came out great and there is some descent clearance to all the engine components.

Still working on the intake manifold, somehow I think its going to take longer than I originally thought, hoping to start on the intercooler mounting next week though.

Still working on the intake manifold, somehow I think its going to take longer than I originally thought, hoping to start on the intercooler mounting next week though.

The welding continues

Still welding the intake manifold, finally got all the runners attached to the intermediary plate for the plenum, need to grind the welds clean and smooth out the transition from the plenum to the runner. Also doing the final welding on the downpipe/mufflers, installed the hanger bracket, once the welding is complete on the exhaust downpipe and manifold then I will be welding the frame hanger bracket to the center of the X brace on the frame.

Intake manifold fabrication

Yesterday I started intake manifold welding, please keep in mind this is about the second time I have tried to TIG weld aluminum and its my first time trying to weld a thick material (3/8") to thinner material (1/8"), I had many problems, nothing that won't be cleaned up. Also I found out from my boss a way to get a better weld when welding materials with substantial thickness difference (preheat the thicker material with a propane torch), which I will be trying out tomorrow, so I hope it helps with welding quality and speed, so onto the pictures. What you are seeing is the 3/8" plate that will get welded to the intake plenum, with the trumpet style intake runners that should speed up air velocity, the curved entry to the intake runners should also the airflow into the ports and keep runner turbulence to a minimum. After this I will be welding the runners to the intake manifold flange (which is 1/2" aluminum) and after that I will be welding on the intake plenum.

Progress is coming

Sorry everybody about the lack of posts, there is progress, started welding the intake manifold last night but forgot my camera, also was going to finish the exhaust welding this weekend but had the exhaust hanger bracket lasered out of mild steel, not stainless like the rest of the exhaust is made of. I will have pics to post tonight.

Also on another note the next 2 or 3 weeks might be slow with this build, my daily driver (86 Fiero GT) needs a new engine/tranny combo, so I am swapping in a 3800SC 4spd muncie transmission (from the original 2.8L auto), right now I am waiting on the flywheel, motor mounts and wiring harness, hoping to make the swap in one weekend.......

Also on another note the next 2 or 3 weeks might be slow with this build, my daily driver (86 Fiero GT) needs a new engine/tranny combo, so I am swapping in a 3800SC 4spd muncie transmission (from the original 2.8L auto), right now I am waiting on the flywheel, motor mounts and wiring harness, hoping to make the swap in one weekend.......

New brake parts

With great thanks to John Powell from Powell Motorsports he has hooked me up with some front brake calipers, I will let the pics do the talking.

Exhaust mockup complete

Fabrication of the exhaust is nearing completion, all the cutting and tack welding is complete, just need to do the final welding and mount the exhaust hanger. I did in the end cut off the mufflers and install a S-bend in the pipes to offset the 1" needed to have the mufflers exit center on the car

.

Resiko Terkikisnya Elemen Defogger

Kebanyakan mobil keluaran baru sekarang, sudah dilengkapi dengan perangkat defogger, yang membuat kaca belakang mobil terbebas dari embun cuaca dingin menerpa.

Piranti ini bisa dibilang hampir tidak pernah rusak. Kerusakan biasanya terjadi pada saat pemilik mobil yang ingin mengganti kaca film belakangnya dengan kaca film jenis lain.

Elemen defogger dapat terkikis pada saat kaca film lama dilepas meskipun dilakukan dengan perlahan dan hati-hati. Meskipun demikian tidak berarti setiap kali penggantian kaca film pada kaca belakang akan menyebabkan elemen defrogger terkikis, tidak ada probabilitas pasti terkikisnya elemen defogger pada saat melepas kaca film lama, hanya type-type mobil tertentu yang di sinyalir defoggernya lemah, sebagian besar tidak bermasalah dengan elemen defogger saat kaca film lama dilepas.

Lemahnya defogger juga berpengaruh dari umur pakai mobil, kondisi perawatan mobil yang terakumulasi menahun, spt parkir hujan dan terjemur, dan lain-lain. Umumnya mobil eropa memiliki elemen defogger yang kuat, tapi bukan berarti mobil type tersebut risk free 100%.

Untuk mobil baru bila ingin memakai kaca film tertentu yang tidak menjadi standar kaca film yang diberikan oleh showroom/dealer mobil, maka sangat disarankan untuk tidak memasang kaca film standar showroom/dealer sehingga tidak beresiko defogger terkikis dan pemasangan kaca film lebih cepat dengan hasil yang maksimal.

Resiko defogger terkikis sepenuhnya menjadi tangggungan pemilik mobil saat mengambil keputusan mengganti kaca film belakang, maka percayakanlah pemasangan/penggantian kaca film pada workshop handal dan berpengalaman, karena umumnya memiliki trik-trik tertentu agar resiko defrogger terkikis minim.

Silakan datang ke workshop Monza Autosport untuk mendapatkan pelayanan dan hasil lebih baik yang didukung teknisi-teknisi berpengalaman dan handal.

Piranti ini bisa dibilang hampir tidak pernah rusak. Kerusakan biasanya terjadi pada saat pemilik mobil yang ingin mengganti kaca film belakangnya dengan kaca film jenis lain.

Elemen defogger dapat terkikis pada saat kaca film lama dilepas meskipun dilakukan dengan perlahan dan hati-hati. Meskipun demikian tidak berarti setiap kali penggantian kaca film pada kaca belakang akan menyebabkan elemen defrogger terkikis, tidak ada probabilitas pasti terkikisnya elemen defogger pada saat melepas kaca film lama, hanya type-type mobil tertentu yang di sinyalir defoggernya lemah, sebagian besar tidak bermasalah dengan elemen defogger saat kaca film lama dilepas.

Lemahnya defogger juga berpengaruh dari umur pakai mobil, kondisi perawatan mobil yang terakumulasi menahun, spt parkir hujan dan terjemur, dan lain-lain. Umumnya mobil eropa memiliki elemen defogger yang kuat, tapi bukan berarti mobil type tersebut risk free 100%.

Untuk mobil baru bila ingin memakai kaca film tertentu yang tidak menjadi standar kaca film yang diberikan oleh showroom/dealer mobil, maka sangat disarankan untuk tidak memasang kaca film standar showroom/dealer sehingga tidak beresiko defogger terkikis dan pemasangan kaca film lebih cepat dengan hasil yang maksimal.

Resiko defogger terkikis sepenuhnya menjadi tangggungan pemilik mobil saat mengambil keputusan mengganti kaca film belakang, maka percayakanlah pemasangan/penggantian kaca film pada workshop handal dan berpengalaman, karena umumnya memiliki trik-trik tertentu agar resiko defrogger terkikis minim.

Silakan datang ke workshop Monza Autosport untuk mendapatkan pelayanan dan hasil lebih baik yang didukung teknisi-teknisi berpengalaman dan handal.

Downpipe and exhaust mock up

Its been a couple days, but I have completed the mock up of the downpipe and exhaust systems, I still need to make the exhaust hangers and there is a slight issue/problem that most people might just let go, but its really bugging me.........the dual mufflers are 1" off center (with a slight twist but thats a really easy fix), in reality I might be able to hide the error with creative bumper design/exhaust tip design, but I am going to look into shifting it tomorrow before I do the final welding to the unit.

Turbo mounting and downpipe fabrication

Today I mounted the turbo to the manifold for the first time, also started fabricating the downpipe. Everything is extremely tight, with very tight clearances to the motor mount and jack shaft, but in the end it should be good. I could have mounted the turbo differently but I didn't want to make the exhaust piping too crazy, with the current layout the two mufflers will exit center on the bumper of the car. Still contemplating what tip to use, but in reality its going to be a long time before I have to mount one.

Subscribe to:

Posts (Atom)