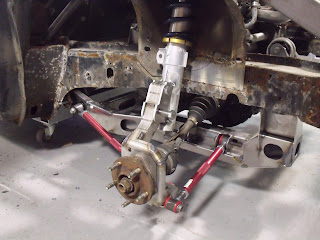

Today was more of what I did yesterday, with one exception, I got the struts mounted to the knuckles. The new strut ears aren't tack welded on very well since my TIG welder can't handle 1/4" alum, I will send them out to be welded sometime in the following week. I might adjust the height of the strut a bit more to get them sitting a little lower and closer to the drive shaft, there is still about a inch until I get interference at full extension of the strut.

88 Custom engine cradle fabrication part 4 and rear suspension mock up

So it was a very big day today, I got the engine and upper transmission mounts welded up and installed, there was a re-design of both mounts. The engine mount is an LSJ Ion/Cobalt mount now although the upper transmission mount is still a L-series Saturn mount I redesigned the mount on the transmission so that it sits lower on the transmission and gives me much better clearance for the shifter cables.

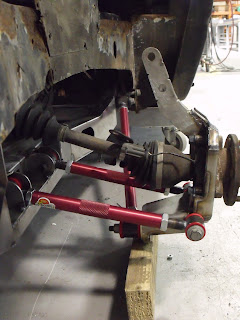

I also removed the engine cradle from the jig today, installed the tube for the front mount location and trailing arm bolt location, since the jig was removed I was able to start mocking up the rear suspension with the fully adjustable control arms and trailing arms with polyurethane bushings.

Lastly I started welding up the rear knuckles, I only did some tack welding since my welder at work is only a light duty TIG welder, I will send the pieces off to the other plant where my intake manifold was welded.

Keep in mind that most of the pieces don't have final welds done to them yet, I have only did tack welding everywhere in case there is a problem and I need to modify pieces.

I also removed the engine cradle from the jig today, installed the tube for the front mount location and trailing arm bolt location, since the jig was removed I was able to start mocking up the rear suspension with the fully adjustable control arms and trailing arms with polyurethane bushings.

Lastly I started welding up the rear knuckles, I only did some tack welding since my welder at work is only a light duty TIG welder, I will send the pieces off to the other plant where my intake manifold was welded.

Keep in mind that most of the pieces don't have final welds done to them yet, I have only did tack welding everywhere in case there is a problem and I need to modify pieces.

Custom 88 Knuckles

So I formed up the knuckle pieces today that CCFiero had been designing, they came out really good, need to double check a couple holes and do a little cleaning up so I can weld them, which will be happening this weekend.

Engine mounting and Frame welding part 3

Today was a big day, the engine cradle and engine were test fit back into the car and everything went well, as I thought the engine mount and upper tranny mount need to be re-made, but with the redesign the mount will be simpler and look cleaner.

Engine mounting and Frame welding part 2

Today was a big day, got a few things done to the engine cradle, I got the two transmission mounts and lateral cradle pieces welded in plate, they are only tack welded right now until I can verify that all the dimensions are correct. I had a small problem with the location and had to move the engine forward aprox 1.5" to ensure that the driveshafts were in line with the center of the hub, when I did this the front lateral cradle brace was hitting the transmission mount and I had to cut out a chunk of it to make the space, I am going to have to look at re-enforcing the piece at a later date. Also another problem became apparent when I went to install the header, turbo downpipe and mufflers, I tried to keep the same dimension and location of the rear lateral cradle piece but the downpipe is hitting the piece and I will need to lengthen the downpipe slightly to get the proper clearance to the frame.

Also today I got all the pieces lasered for the rear knuckles, they are cut out of 3/8", 1/4" and 3/16" stainless steel, they will require forming and a lot of welding.....looks like fun for next week. A big thanks to CCfiero for doing the engineering of the rear knuckles......can't wait to start these.

Lastly all the pieces are in for the adjustable rear control arm and the trailing link arm, the shopping list includes, alum radius rods, 3/4" left and right fine threaded rod, steel tubing and polyurethane inserts. But why not use heim joints? heck that would have been a lot easier, I can get them from anywhere, personally I don't know why I can't find adjustable bushing inserts because for this project I don't think that heim joints are a good idea. Personally I don't like heim joints, I've had bad luck with them and especially on a car that I would like to drive on the street.........if I was building a race car they would have been heim joints.

Also today I got all the pieces lasered for the rear knuckles, they are cut out of 3/8", 1/4" and 3/16" stainless steel, they will require forming and a lot of welding.....looks like fun for next week. A big thanks to CCfiero for doing the engineering of the rear knuckles......can't wait to start these.

Lastly all the pieces are in for the adjustable rear control arm and the trailing link arm, the shopping list includes, alum radius rods, 3/4" left and right fine threaded rod, steel tubing and polyurethane inserts. But why not use heim joints? heck that would have been a lot easier, I can get them from anywhere, personally I don't know why I can't find adjustable bushing inserts because for this project I don't think that heim joints are a good idea. Personally I don't like heim joints, I've had bad luck with them and especially on a car that I would like to drive on the street.........if I was building a race car they would have been heim joints.

Rear strut and camber plate test fit part 1

Quick update tonight, today was the first test fit of the rear coilover setup, it is a bilstien insert shock with a custom made coilover assembly. This isn't the final rendition of the unit, these were the units that I used on my ION, the housing will need to be modified with new strut to knuckle mounting plates and possibly a new design for the rear swaybar, but I won't be able to check that until the new engine cradle gets mounted. Also you might notice that the shock angle is incorrect for a 88 style suspension, something that I overlooked until I did the test fit today is that the suspension tower at the top on the 84-87 is several degrees different than the 88's, because of this I will need to calculate the difference in the towers, and either adjust the current spring/strut mounting plate or cut a thicker one and machine it to the correct angle so the struts sit at the proper angle.

88 Custom engine cradle fabrication part 3

Today was a big day, I had the remaining pieces which I had designed yesterday lasered, formed and welded together. I did a dry fit of the final pieces and the brackets for the transmission mounts, it fit well, needs a little trimming and before I weld it I need to double check the final location of the engine, verifying it is centered properly on the wheel hubs and level, here's the pictures of today's progress.

Subscribe to:

Posts (Atom)